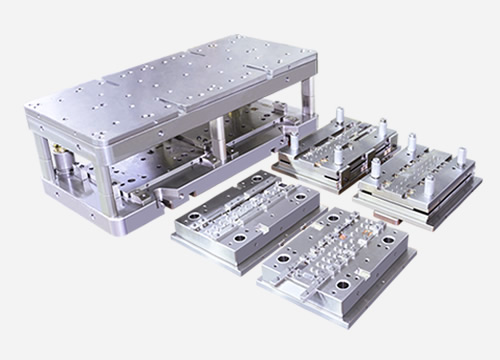

Injection Mold

Product Desciption

Plastic injection moulding is the process of melting plastic pellets (thermosetting/ thermoplastic polymers) that once malleable enough, are injected at pressure into a mould cavity, which fills and solidifies to produce the final product.

Injection Moulding is used to make a variety of widely used products. If you look around your desk/ home you will find a multitude of injection moulded products, from bottle tops, remote control casing, console covers, syringes and most plastic made products.